Precision Shaft

・Part of Automotive, Oil Hydraulic Equipment, Pneumatic Component, Medical Equipment, Instrument, Analytical Instrument, Robot, Food Equipment

・DC Motor, Spindles Motor, Spindle for Printer, Part of P

Classification:

Products

Product display

Product accessories:

Hotline:

Precision Shaft

Precision Shaft

Precision shaft pursue more high precision for more silent, high rotational speed, long life.

Basic Precision

| Basic precision | |||||||||

Dimensions | |||||||||

| |||||||||

Precision | |||||||||

| |||||||||

| ・Material characteristic | |||||||||

| ・Precision is differ according to the raw material, dimension and shape. |

Non-Magnetic and High Hardness Shaft

| Shaft having excellent non-magnetic, wear and abrasion resistance and corrosion resistance characteristic. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Possible become to the surface hardness HV700 by special processing. | ||||||

| ・Details of non-magnetic and high hardness material | ||||||

| ・Other precision follow the specification. |

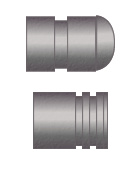

End Face

| Possible to provide high precision R(A) face by grinding processing. | |||

Dimensions | |||

| |||

Precision | |||

| |||

| ・Differ according to each shape, total length and material. | |||

| ・Precision is not changed by heat treatment. |

| Possible to provide high precision by grinding processing F face. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Differ according to each shape, total length and material. | ||||||

| ・Precision is not changed by heat treatment. |

| Possible to provide high precision by grinding process chamfer shaped. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Differ according to each shape and material. | ||||||

| ・Precision is not changed by heat treatment. |

Groove

| Possible to process with high hardness material after heat treatment by grinding processing. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Shaft having excellent straightness.(Precision is not changed by heat treatment.) | ||||||

| ・Differ according to quantity by means of using exclusive machine. | ||||||

| ・Differ according to each shape and material. |

Step

| High precision and low cost mass-production by grinding processing. | |||||||

Dimensions | |||||||

| |||||||

Precision | |||||||

| |||||||

| ・Differ according to quantity by means of using exclusive machine. | |||||||

| ・Differ according to each shape and material. |

D-cut

| High precision and low cost mass-production by grinding processing. | ||||

Dimensions | ||||

| ||||

Precision | ||||

| ||||

| ・Differ according to quantity by means of using exclusive machine. | ||||

| ・Differ according to each shape and material. |

Knurling

| Processing as the detent of small diameter and short products. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Impossible of processing to the high hardness material. | ||||||

| ・Please check the swell processing if you need high precision with high hardness material. | ||||||

| ・Lost the precision when it do the heat treatment. |

Knurling

| Processing as the detent of big diameter and long products. | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Impossible of processing to the high hardness material. | ||||||

| ・Lost the precision when it do the heat treatment. | ||||||

| ・Differ according to each shape and material. |

Swell

| Using for the detent of high hardness and high precision shaft. | |||

Dimensions | |||

| |||

Precision | |||

| |||

| ・For liquid stopper of adhesive. | |||

| ・Keep the high precision to hard material. | |||

| ・Unchanged basic precision if to the heat treatment.Differ according to each shape and material. |

Hole(inner)

| Sac hole・Through hole | ||||||

Dimensions | ||||||

| ||||||

Precision | ||||||

| ||||||

| ・Differ according to material. |

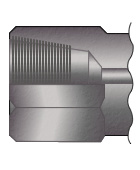

Screw

| Male screw | |||

Dimensions | |||

| |||

Precision | |||

| |||

| ・Differ according to the material. |

| Female screw | |||

Dimensions | |||

| |||

Precision | |||

| |||

| ・Differ according to the material. |

Surface Treatment

| Surface treatment |

Plating |

| Chromium・Nickel・Smoothness・Gold |

Coating |

| DLC・TiN・Teflon・Flourine・Blackening |

Heat Treatment |

| Vacuum carburizing・Oil quenching・High frequency・Nitriding・Tufftride |

| ・Please contact us if you need other processing. |

Previous

Next

・Part of Automotive, Oil Hydraulic Equipment, Pneumatic Component, Medical Equipment, Instrument, Analytical Instrument, Robot, Food Equipment

・DC Motor, Spindles Motor, Spindle for Printer, Part of P

View Details

LeadScrewTNKprovideshighprecisionandsmalldiameterleadscrew.It’spossibletoproduceforusminimumpitchscrewprocessingonminimumdiameterofsmallerthanφ1.0mminanewfieldofgrindingleadscrewtoprovide4000kpcsamont

View Details

Online Message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Can meet your needs of a variety of materials!

WeChat Public Number

Address:

Foreign companies

Established:April 20, 1994